Custom Stamping & Engineering

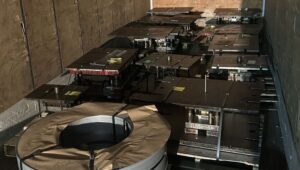

ACRO Metal Stamping provides USA-based custom stamping and engineering utilizing the latest technology. We are a prime producer of precision stampings in all shapes, sizes, and materials, specializing in running progressive and compound dies produced in our in-house toolroom.

The Trusted Choice for

Precision Metal Stamping

MANUFACTURED IN THE USA

TIGHTER TOLERANCES

IN-HOUSE

TOOL ROOM

DIE DESIGN &

RE-ENGINEERING

Higher quality and larger cost savings are within reach

Experts in tight tolerance and complex metal component manufacturing

For over 75 years, ACRO Metal Stamping has been a low cost stamping and assemblies supplier. We build and maintain all of our own dies in-house, reducing cost, improving quality, and generating faster turnaround times. Plus our engineers can help adjust your design for the lowest cost production, while providing higher quality, and better manufacturability. ACRO also has more Servo Presses than any other job shop in the Midwest, making ACRO Metal Stamping the trusted choice for all your stamping needs.

Are you looking for higher quality & better manufacturability?

Services & Capabilities

Need a specialist in progressive or compound dies?

Testimonials

Christie Tyler

Christie TylerBuyer/Planner

Gregg Hackney

NORAM

North American Clutch Corporation

Charles Geurts

Charles GeurtsSupply Quality Engineer

Steve Brinker

Steve BrinkerPurchasing and Logistics Manager

Chris Miller

Chris MillerSenior Buyer

Kirk Tyler

Kirk TylerMaster Scheduler