Acro News & Information

Debugging Dies Virtually

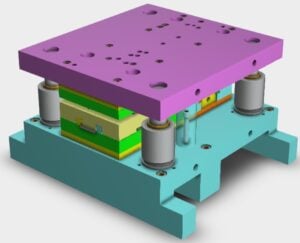

We at Acro were so fortunate to add a new designer to our Famiy this year; who brought a fresh understanding of the latest technology. We’ve now been able to utilize some of the capabilties build into the specifically for metal stamping plug in for solidwards called Lgogpress that we use. Most beneficially recently; we’ve been able to utilize the “Die Debugger”; which allows us to virtually run the die in one of our presses. …

Read MoreNo Boxes, No Hassle—Just Dependable Deliveries

Smarter Packaging. Dependable Deliveries. ✅ Reusable Totes ✅ Custom-fit Packaging ✅ Custom Labeling ✅ Monthly Shipments ✅ In-House Services ✅ Flexible Sourcing ✅ Built for Growth ✅ Reliable & On Time ✅ Zero Carboard Waste ✅ Cost Effective ✅ Sustainability ✅ Reduced Packaging Waste Monthly Delivery-Ready to Go Out the Door! Best thing is… not a single cardboard box used! We worked with our customer to develop a reusable tote solution that fits the 10+…

Read MoreConverting 4-Slide Into Standard Vertical Stamping

“Convert our old, 4-slide tooling into standard vertical punch press tooling and deliver parts to us in just two weeks.” At Acro, we welcome challenges. Solving tough problems is what we do best. We had a buyer approach us as a new customer in dire need of parts to keep their supply chain intact. Their previous metal stamper had unexpectedly closed its doors, creating a production emergency. Even before the purchase order was finalized, we…

Read MoreDeep Drawing Half Hard Brass Is Hard

At Acro, we have a lot of experience with deep drawing a wide variety of materials; but they are usually annealed or soft temper. Recently a customer came to us with a challenge to do a 2 steep deep draw out of Half Hard Brass (the temper and Tin Content, make this difficult). As, a matter of fact, HH Brass is more difficult to draw than annealed stainless steeel. Our stamping specific modeling software calculated…

Read MoreA Challenging Point: Sharp Teeth

Stamping to a sharp point presents a unique challenge in our industry. The finer the point, the more quickly tooling wears down-and the higher the risk of issues like part distortion, burr formation, and inconsistent tolerances. At ACRO, we specialize in overcoming exactly these kinds of challenges. Recently, we completed a project involving a series of precision parts that not only had to taper to exceptionally fine points but also required a precise radius profile.…

Read MoreOur Smallest Washer Ever

Do you want to impress a toolmaker from another stamper? Show them a part with a hole so small they can’t see it with their name eye! We recently took on production of a washer so small. it pushed the boundaries of what our tooling can do — and we’re proud to say, challenge accepted and conquered. This washer had an incredibly small inside hole — so small, in fact, that none of the commercially…

Read MoreMore Dies Transferred to Acro

Whether it as it was in this case, where the previous stamper had to close their doors, or you are just looking for savings via efficiency; Acro can retrofit your old tools to run in our state of the art servo presses. These series of parts are a perfect fit for Acro, as they encompass both deep drawing and they have tight tolerances. Our In-House toolroom, is able to optimize all kinds of older dies.…

Read MoreAcroflex Helps Insulate Power Plant

Acroflex is a proprietary product that has had a million uses going all the way back to the 1940s. Today, it is most often used to hold Insulation on pipes in Power Plants. See below for some of the ways it has been used in its 80+ year history & see how you can use it.

Read MoreDon’t Let Tariffs Break Your Supply Chain—Go Local. Stay Strong. Choose Acro Metal Stamping.

With the U.S. considering significant tariff hikes, now is the time to reevaluate how you’re managing your supply chain. Global supply chains have proven vulnerable—whether it’s due to geopolitical shifts, shipping delays, or unpredictable foreign tariffs. Businesses that rely on overseas parts and materials are now facing added risk, potential cost spikes, and shipping delays that can erode margins and disrupt your production. That’s Where Acro Metal Stamping Comes In. At Acro Metal Stamping, we…

Read MoreProgressive Die Stamping in Action

This video is of a progressive die stamping 10-gauge (.135” thick) cold-rolled steel, producing an automotive mounting bracket. This very die was built in-house over 10 years ago—and it’s still running strong! With our on-site toolroom, we proactively maintain and repair tooling to ensure long-lasting performance and consistent quality. That’s why customers trust us—not only for new die builds but also for transferring dies from other suppliers to keep their projects running smoothly. Need a…

Read MoreExplaining The Pinch Trim

When trimming the edge of a part, especially drawn cans & cups; there are 3 Options for the finish on the end. Just a raw formed edge can be uneven both in its height and in it’s cross section. One of the older, and still the most precise ways of controlling that edge, is to machine it (often times turning in a lathe). The image Below shows a rough drawn part on the left and…

Read MoreUnderperforming Supplier? Discover Why Acro Metal Stamping is your Trusted Source for Stamped Parts

As the new year rolls around, you often hear the phrase, “New Year, New Me.” but why not try, “New Year, New Metal Stamping Supplier”? Explore success stories from our current customers to see why they continue to trust us as their go-to source for high-quality parts. From Dual-Source to Primary Supplier: A Success Story In 2020, a customer partnered with us as a dual-source supplier to address challenges they were facing with their existing…

Read More

MANUFACTURED IN THE USA

TIGHTER TOLERANCES

IN-HOUSE TOOL ROOM